Installation made easy with Harmony® XB5R plastic and XB4R metal wireless and battery-less pushbuttons.

The Harmony XB4R-XB5R offer of wireless and battery-less interfaces are used for various building utilities (automatic doors, lighting, etc.) and industrial applications (conveying systems, automotive, MMM, logistics, food and beverage). They are based on two types of device – transmitter and receiver – which communicate via 2.4GHz radio transmission (free worldwide band) Zigbee Greenpower certified using an accessory.

Simplified installation

- Lower installation costs and time

- No setup needed due to ready-to-use Plug-and-Play package

- Freedom of mobility around the machine or process

- Ideal solution when you need to add or move a control function

- Compatible with all XB5 & XB4 actuators (not suitable for safety applications).

Easy maintenance

- Requires no battery maintenance and helps to ensure permanent availability

- Maximum availability of control functions

- Visual feedback option to easily check functioning

- Possibility to change frequency

- Highest cybersecurity levels using ZBRZ1 tool

- Eco-friendly Green technology

- Minimizes post-installation maintenance.

Designed for industrial environment with proven robustness

- High resistance to contamination from dust (no cable entry)

- No risk of cable damage or loose screws on the transmitter

- Zigbee Green Power using ZBRZ1 tool

- Ø 22mm operating head available in plastic (ZB5) and metal (ZB4) and Ø 40 mm black spring return mushroom head allowing operation with gloves

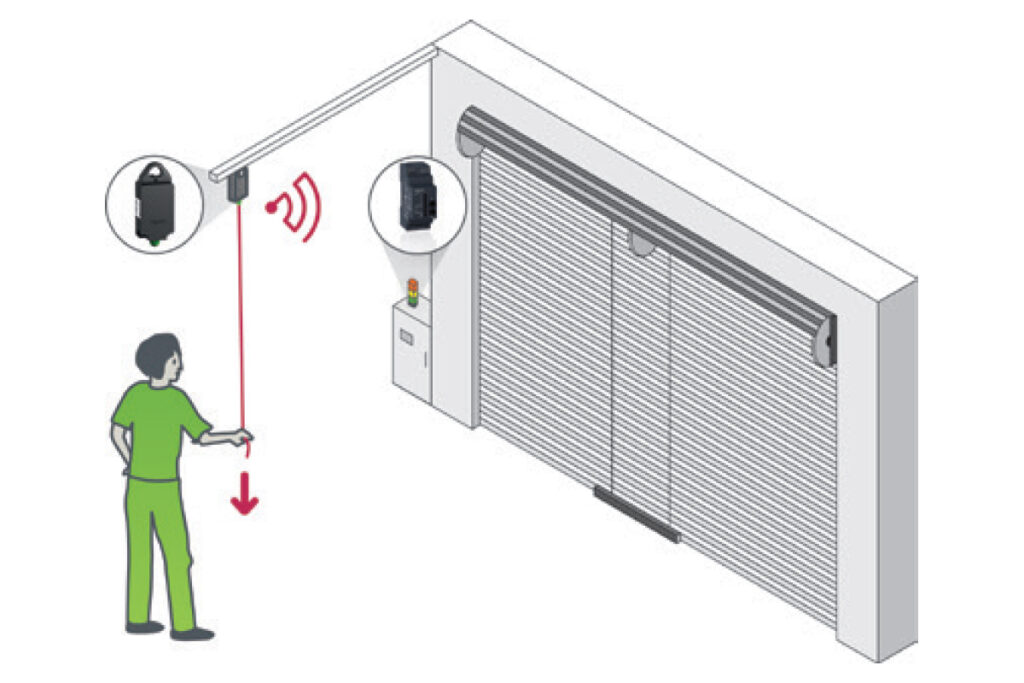

- For automatic doors, the rope pull switch command can be set anywhere

- Suitable for the most demanding environments, depending on the model, up to IP69, for external use from -40 to 70°C.

Assured performance according to distance

- 25m with the receiver installed in a metal electrical cabinet

- Boosted to more than 250m with the use of an external relay antenna with the receiver installed in a metal electrical cabinet

- 100m in free space.

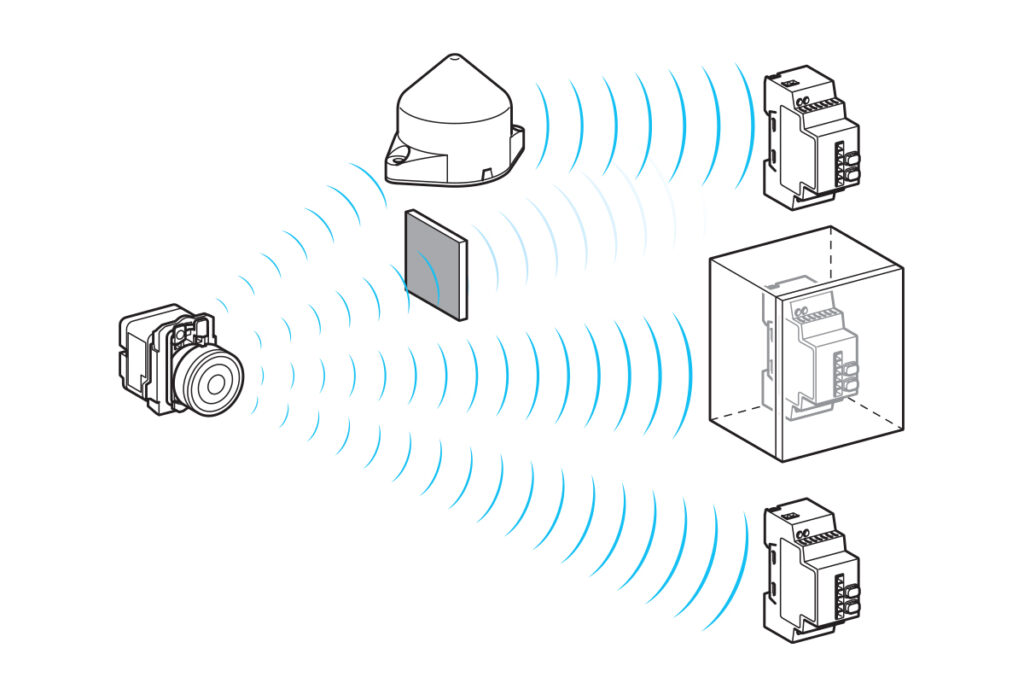

The Harmony wireless and batteryless pushbuttons range enables remote control of a relay (receiver) by means of a pushbutton (transmitter). The control is by radio transmission where the transmitter is equipped with an electric generator that converts mechanical energy, produced when the pushbutton is pressed, to electrical energy. A radio-encoded message with a unique ID code is sent as a single pulse to one or more receivers located several dozen metres away (see Figure A).

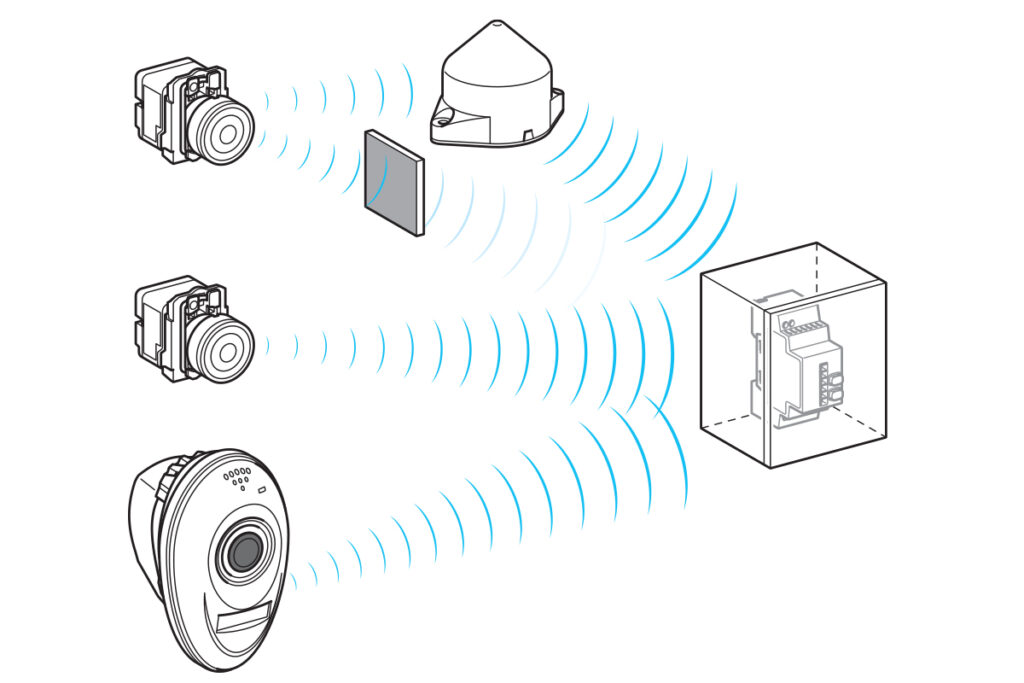

A single receiver can also be actuated by up to 32 different transmitters (see Figure B).

In order to avoid any conflict of multiple transmission from different transmitters, a minimum time frame of 10ms is required between each radio transmission. Depending on the application, a relay-antenna can be used to get round an obstacle that impedes transmission or to increase the range (see Figure A and Figure B). The possible distance between a transmitter and a receiver is approximately: – 100m where there are no obstacles – 25m if the receiver is installed in a metal housing or in a closed metal enclosure – 300m if a relay-antenna is located between the transmitter and the receiver (receiver installed in a metal housing or in a closed metal enclosure) These distances could be drastically reduced in industrial environments where factors such as radio interference, obstacles, or electromagnetic interference may impede the signal. As a consequence, some radio signals may not be received by the receiver.

The wireless and battery-less pushbutton reduces installation time and cost since no wiring and associated equipment is required between the transmitters and the control panel. This technology also allows an operator to be mobile or to have a control mounted on board a vehicle (trolley, truck, etc.). The pushbutton is always available and requires no maintenance (no battery needed). The mobile box ZBRM21 or ZBRM22 associated with its support function is adapted for static and mobile applications mounted on vehicles. The range also includes a new wireless and battery-less rope pull switch designed for easy operation of automatic doors. This switch can be either mounted directly on the panel or between two ropes close to the automatic door. This enables the forklift driver or pedestrian to open or close the door by pulling the rope, where the mechanical energy produced is transmitted as a radio message to the receiver in the control panel (see Figure C).

This technology (radio-encoded message sent as a single pulse) cannot be used for hoisting applications (“up/down”, “right-left” movements, etc.) or safety applications (Emergency Stop pushbuttons, etc.). For these applications, it is recommended that Harmony XB4 and XB5 wired pushbuttons or the XAC range of pendant control stations be used.

For further details contact your Powerbase Branch or click here