This quality general-purpose drive is a perfect match for a wide range of applications. iC2-Micro performs with unsurpassed reliability even in complex applications. It gives you user-friendliness, condensed functionality, and easy commissioning, all in a powerful

compact package.

Next generation

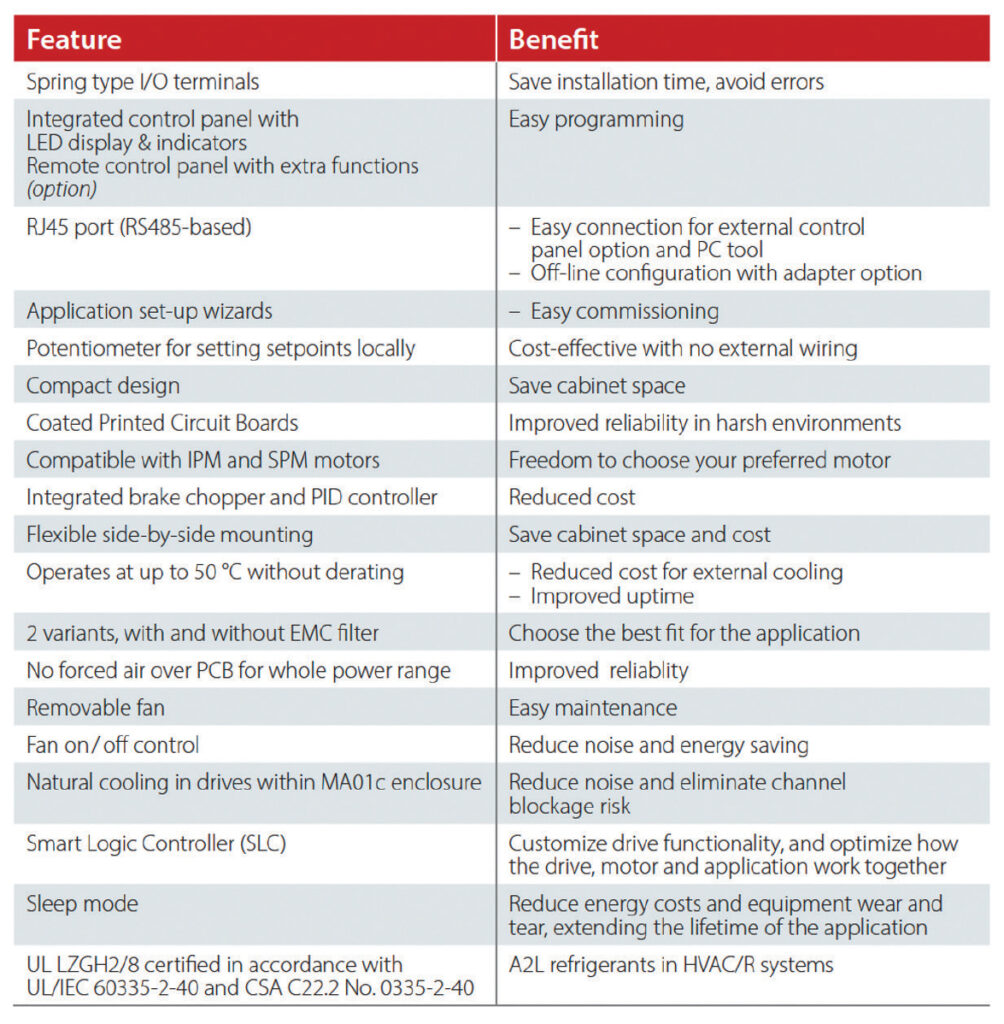

More compact, intelligent, and powerful than its predecessor, the iC2-Micro now succeeds VLT® Micro Drive FC 51. This reliable and durable drive is also even easier to use and install. You can reduce system complexity and cost whilst maintaining full performance.

High performance

This drive gives you excellent motor control and mechanical brake performance. New features include torque open loop control, locked rotor detection, permanent magnet motor control, built-in control panel and, of course, connectivity with our MyDrive® Suite digital tools.

Highly integrated design

iC2-Micro contains an integrated control panel, potentiometer, RFI filter, brake chopper, and intelligent cooling to reduce the need for external components.

Easy retrofit

Designed to smoothly replace VLT® Micro Drive FC 51 in established plants.

Fits your application

You can use the same drive in diverse processes, since the iC2-Micro is designed to optimise a wide range of applications such as;

• Pumps

• Fans

• Material handling

• Conveyors

• Mixers

• Packaging machines

• Palletisers

• Textile machinery

iC2-Micro: the convenient drive

With focus on streamlined operation, iC2-Micro keeps your task simple. The iC2-Micro offers a software tool to save time, improve reliability, and reduce risk.

Commissioning and service are easier than ever with MyDrive® Insight commissioning and monitoring tool. For fast and easy configuration and commissioning, MyDrive® Insight enables you to control the drive from a PC for operations such as starting or stopping the drive, set references, set direction, reset, and coast of the drive. Once the drive is in operation MyDrive® Insight monitors the drive and collects data for troubleshooting, maintenance, and service. Technicians can use MyDrive® Insight not only to configure parameter settings, but also to back up and restore these settings during service.

Access to application guide and other documentation is faster than ever using the QR code located on the front of the drive for convenient scanning. By scanning the QR code with a smart device, you can access the iC2-Micro webpage to quickly find technical literature, technical data, drawings etc.

Two variants with and without EMC filter, according to your needs. There’s no need to pay for an EMC filter when it’s not required! But with the integrated EMC filter you can use shielded motor cables and remain compliant with EN/IEC 61800-3, class C1 or C2 for your applications. This can help you save space in the cabinet and reduce handling process.

Intuitive control panel simplifies commissioning, operation, and service. The control panel features a 6-digit 7-segment LED display, status indicators, clear navigation buttons, and built-in frequency setting potentiometer.

Streamlined mounting and service thanks to simple wiring with spring type I/O terminals and removable fan. For single-phase 230 V drives in the power range up to 0.75 kW, they even support natural cooling without a cooling fan. The detachable cooling fan design with on-off control makes maintenance easily, improves the cooling efficiency, reduces service cost, and minimises environmental noise.

Operates at 50 °C ambient temperature at full load, iC2-Micro is designed to perform optimally under full load at 50°C ambient temperature, and up to 55°C with derating. This gives you cost savings since there is no need to install extra cooling equipment, nor to oversize the drive.

Save-space thanks to the compact design optimised for book style side-by-side mounting.

PM motor compatibility

You win the freedom to choose the best high-efficiency motor for your application. iC2-Micro provides highly efficient permanent magnet motor control in open loop under VVC+ in the whole power range.

Integrated PID controller

The built-in PID controller ensures solid process control, such as constant pressure or constant flow operation.

Coated PCB

Printed circuit boards coating is as standard against corrosive gases (IEC 60721-3-3). This protection provides high reliability in harsh environments, preventing failures and unnecessary downtime increasing lifetime of the drive.

Integrated brake chopper

A built-in brake chopper saves money and panel space.