A look ahead into the benefits of LED

LED vs Fluorescent: An Introduction

Even today, fluorescent lighting is used extensively across the world in a wide range of applications. If you work closely with lighting, you may be aware of some of the issues which can occur with fluorescent technology. Often these are easily highlighted by a quick look around the site – there will likely be numerous fittings which are no longer working, or if they are all still running, frequent maintenance will be required to ensure they are operating correctly.

LED linear luminaires provide a solution to many of the problems which exist with traditional fluorescent fittings, in this article we will tackle five of the key issues when comparing LED linear fittings to fluorescent fittings.

1. Performance

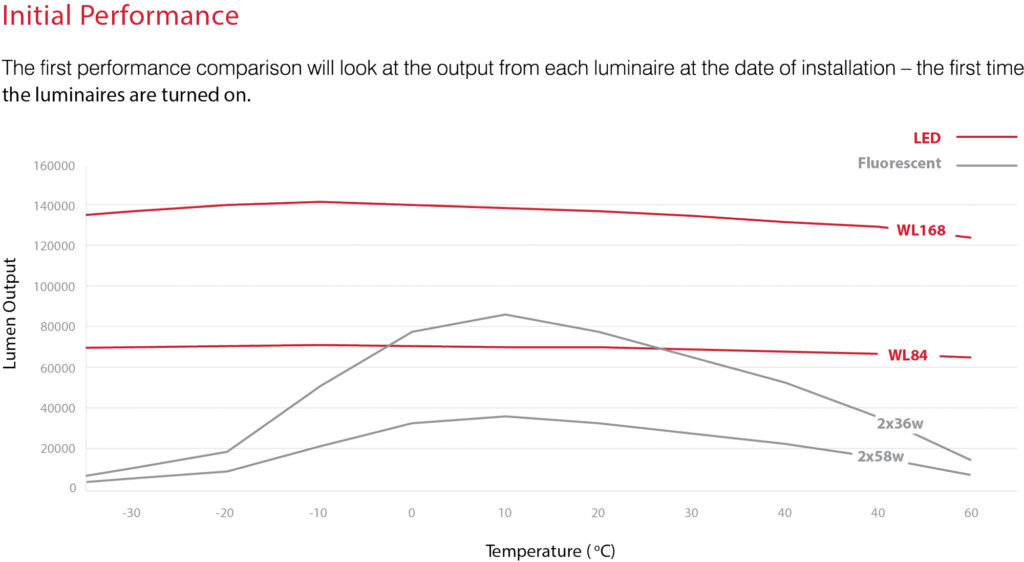

LED luminaires offer some obvious expected advantages; longer life with near 0% failure rate, lower maintenance with no need for costly relamping, more consistent light output without loss of lumens over time and better performance under extreme temperatures, both hot and cold.

2. Higher lumen output of LED over a lifetime

Given the past popularity of fluorescent fittings and the vast numbers which have been installed, there is an ongoing demand for ‘retrofit’ LED products. Raytec luminaires are designed as a direct replacement using the same general dimensions, cable entries and fixing centres. This will allow the end-user to reduce the cost of installation.

The cylindrical design of a fluorescent tube means there is always some degree of wasted light, in contrast an LED luminaire can direct 100% of its output toward the ground or wherever it’s needed.

3. Suitability to harsh environments

An LED luminaire remains largely unaffected by extreme temperatures and harsh environments. Luminaires are often exposed to areas of high vibration and may have to withstand occasional high impact. Fluorescent fittings are susceptible to vibration; the cathode located inside the tube is prone to coming loose which causes the lamp to fail. In contrast, an LED alternative such as SPARTAN uses a number of small profile, surface-mounted LEDs, which will not suffer at all under heavy vibration.

4. Maintenance

Frequent maintenance of fluorescent fittings comes at a significant expense. Luminaires certified for use in hazardous areas are often installed in locations where access is restricted, and gaining access can be a costly exercise. The long life of LEDs, without the need for relamping, means significant maintenance savings over the course of the product life.

5. Other considerations (disposal, emergency performance and quality of light)

Costs of Relamping – With a fluorescent tube having a much shorter life than LEDs, requiring frequent maintenance and relamping, there are two other notable costs associated with frequent relamping which should also be considered – availability and disposal.

Fluorescent fittings contain mercury (considered a hazardous substance). The latest amendments to the RoHS directive will see fluorescent tubes banned in the UK on 25th August 2023. This may in time impact availability here to. As they become more difficult to find, the prices are likely to rise significantly, and once stocks are depleted there will be no availability at all.

The presence of mercury and other phosphors in the fluorescent tubes also means there are strict regulations in place to control their disposal as they are an environmental hazard, bringing with them, substantial costs associated with the proper process of disposal. There are no such hazards or regulations for the disposal of LEDs.

Quality of Output – A noticeable difference between fluorescent and LED fittings is the colour temperature; fluorescents typically offering 3,000-4,000k, providing a ‘warmer’ white light. LEDs are available in a wide range of colour temperatures meaning end users can still specify a luminaire with a warmer output if preferred.

With more frequent failures and performance drops of fluorescents, the length of time in which a site is left with areas of darkness, insufficient light levels, or poor uniformity are much higher. This has an impact from a health and safety perspective and heightens the level of risk on-site. This issue will also worsen under emergency conditions where fluorescents often fail when suddenly switching to run at lower power. Reliability of LEDs to offer sustained light levels during an emergency is unparalleled.

Summary

As well as delivering improved performance, both in terms of level and quality of light output, the suitability of LED technology to harsh environments makes it a far more consistent and reliable solution compared to fluorescent luminaires.