Electrical fires can be caused by installations that have deteriorated over time, or from hazards due to electrical systems that have not been installed, upgraded, or maintained properly.

The specific source of a fire can come from an electric arc, leakage current, overload, etc. For each of these causes, there is a solution. This article will discuss preventing fire and injury due to arc flashes and arc faults.

Protecting against arc flashes

An electric arc is a very rapid release of energy in the form of heat and pressure. This can cause severe thermal ignition with explosions and splashes of molten metal. Damage usually has serious potential consequences, causing not only downtime and production losses but also injury to personnel. In the United States, an explosion involving an electric arc occurs on average 5 to 6 times a day. Burn centres there treat more than 2000 people a year for arc-related injuries.

Burns may be the obvious result of an arc flash but also the flash caused by an arc fault can damage the sight, the explosion can damage hearing, the released gases can be poisonous and damage lungs, and the shrapnel effect (fragments projection) can cause serious physical injuries.

The easiest way to limit the energy dissipated by the arc is to limit the duration of the latter by ultra-fast protection. Today there are systems adapted against arc flash phenomenon.

The best of these devices allow for ultra-fast detection (between 1 and 7 ms), measuring fault current via current inputs and light via arc sensor channels. Should a fault occur, the device would minimize burn time by quickly cutting off the current feeding the arc. Traditional arc protection methods do not provide fast enough protection to shorten arc burn times, which is especially critical when an arc develops during maintenance work on the switchgear, jeopardizing personal safely and life. The newest arc fault functionality adds a new dimension to the total performance and availability of the installation, including the reliability of the power distribution system protection.

Protecting against arc faults

Arc fault is a common cause of disaster and is often related to human error or obsolescence of installations. This can include loose terminals or a cable crushed or cropped.

For example, in 1999 Schneider Electric launched the Arc Fault Circuit Interrupter (AFCI) technology in the United States, detecting and switching off the current when a parallel arc is detected. It took 6 years for engineers to develop an arc detector that can detect series arcs as well as parallel arcs. Today, thanks to the introduction of arc fault detection devices (AFDD), installations can be protected from both types of arcs, with current stopped before a fire has the chance to start.

Since 2014, the IEC 60364 standard has recommended the installation of AFDDs in areas where the risk is present. This includes places:

- where people sleep

(e.g. bedrooms, hotels) - where high risk materials are stored (carpentry)

- that are made of combustible materials (wooden houses)

- where fire can spread easily (buildings)

- where goods are irreplaceable (museums)

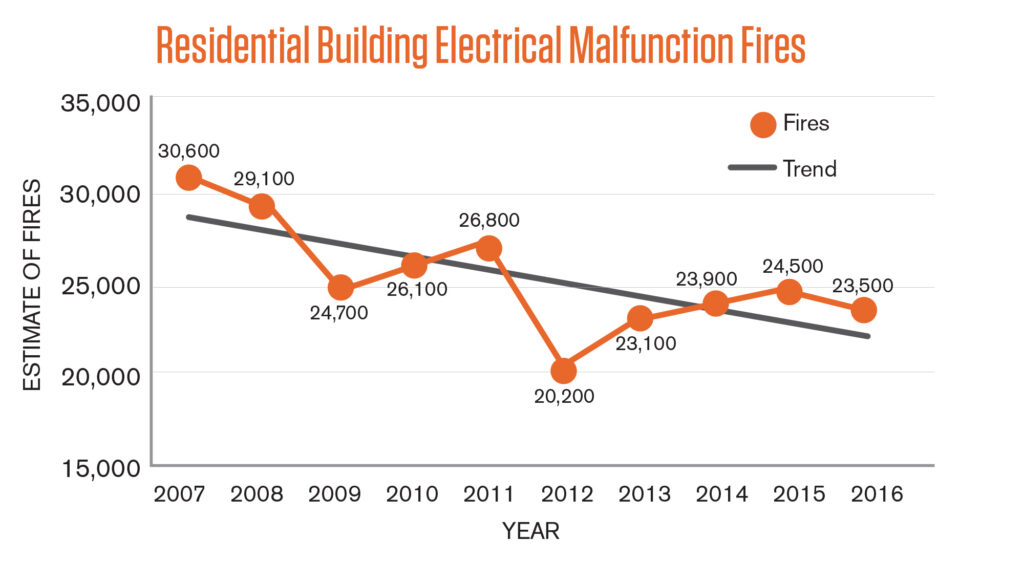

AFDDs are mandatory in the United States and statistics show a positive decrease in the number of residential fires.