for Ex equipment in hazardous areas

Equipment used in hazardous areas particularly in the offshore and petrochemical industries is susceptible to corrosion either from the environment or chemical attack.

For these environments much thought is given to the material the equipment is made of. Things such as stainless steel or non-metallic polymers are commonly considered for the equipment but not much thought is given to cable glands responsible for keeping the unit connected.

Glands are traditionally made from brass which offers fairly good resistance to mild corrosive conditions. However, in the petrochemical process industry, chemicals such as hydrogen sulphides, ammonia, nitric, sulphuric and hydrochloric acids are common and these chemicals all aggressively corrode brass glands.

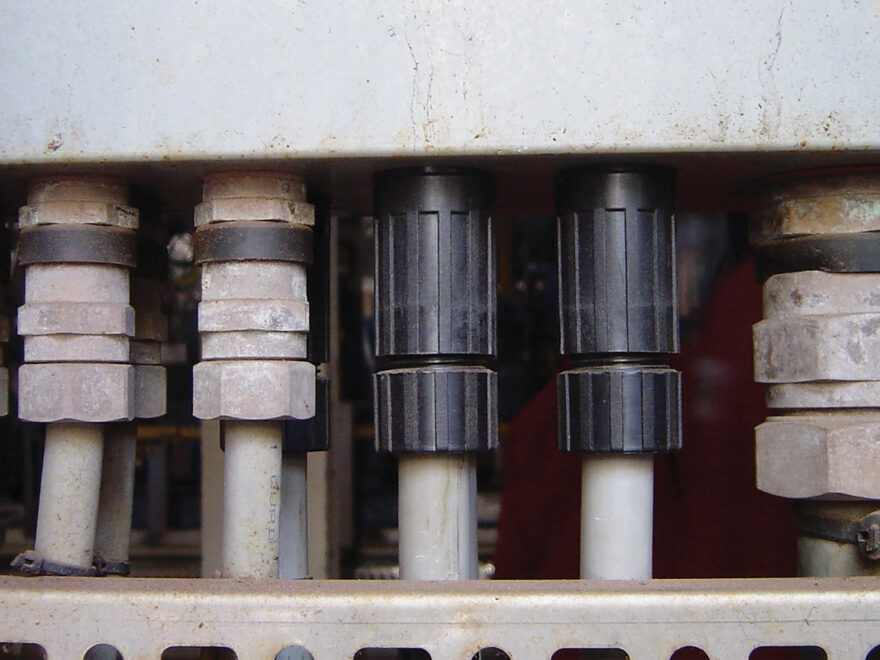

PVC or polycholorprene shrouds are sometimes used as a protection against the ingress of moisture and environmental attack. See Fig. 1. However, shrouds themselves degrade due to heat cycling, UV rays and can be dislodged by mechanical abrasion or heavy water spray. Furthermore, shrouds tend to entrap moisture rather than prevent moisture ingress. When this happens corrosion of the cable gland remains undetected behind the shroud.

The alternative has been to install stainless steel cable glands. However, stainless steel cable glands can cost up to ten times as much as an equivalent brass cable gland. So due to the high cost, specifiers and installers are reluctant to use them. In addition, manufacturers are reluctant to manufacture stainless steel cable glands due to the longer machining time and expense involved.

CCG has overcome all these problems with the unique “Screw On Corrosion Guard®”.

Essentially this device is a screw on mechanical protection device which engages a thread on the outer body of a CCG Exde Armoured Cable Gland. When tightened down the Corrosion Guard® seals against a gasket between the face of the apparatus and the gland entry. An outer nut and compression seal, seals down on the outer sheath of the cable.

The Corrosion Guard® totally encases the metal cable gland giving IP66/68 protection.

The Corrosion Guard® is manufactured from a tough impact and UV resistant non-metallic material which is resistant to almost all chemicals found in the industry.

Apart from being a lower cost alternative to stainless steel cable glands the Corrosion Guard® also makes periodic inspections against corrosion of cable glands less of a need.

Inspections if required are easily achieved without having to partially dismantle the metal parts of the cable gland to inspect corrosion to the armour as is the case with normal metal cable glands.

Corrosion Guards thus offer long term reliability of cable terminations to Ex equipment enhancing the life cycle and safety of the installation.

CCG is a UL Listed ISO 9001 manufacturer with products certified to ATEX, SANS, AS/NZS, CQST and

IEC standards.

Content courtesy of: CCG Cable Glands.