nVent CADDY Rod Lock Spring Steel Rod Hangers

Threaded rod is one of the most commonly used products by contractors of all trades, with a variety of threaded connections being used to support electrical and mechanical systems. While threaded rod is one of the most prevalent products used by contractors, it can be very difficult and tedious to work with.

In evaluating construction and contractor practices, the trend toward making large electrical and mechanical assemblies off-site using standardized operations and processes is undeniable. However, nVent CADDY recognized that the ability of contractors to use pre-assembly for many high-volume applications is severely limited by how standard threaded connections are made. Therefore, the primary objective of the Rod Lock system, which includes a beam clamp, channel nut and anchor screw, is to eliminate the need for contractors to rotate the threaded rod. nVent CADDY recommends Rod Lock channel nuts for use in any building project. This unique product would allow contractors to prefabricate their complex assemblies and then easily lift and lock them into place at the jobsite by pushing the threaded rod supports into the channel nuts. nVent CADDY’s ingenious technology even works with threaded rod with minor burrs or imperfections, helping to eliminate clean-up time or the need to replace damaged threaded rod.

General Features

- Can be fixed on a wall using an anchor screw or available pre-riveted to a variety of nVent CADDY Fasteners

- Release mechanism allowing quick removal of the threaded rod using a pair of pliers

- Works with ¼” threaded rod

- Works with slightly damaged threaded rod ends and minor burrs

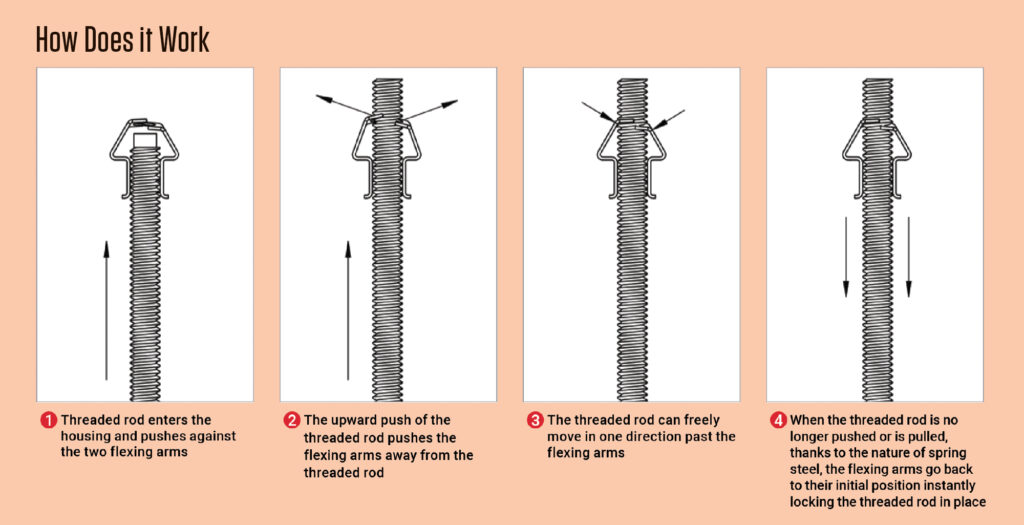

- Easy “push-to-install” design allows installers to simply push the threaded rod through the mounting hole, instantly holding it in position

- Prefabricated assemblies easily lift and lock into place, helping to save time and money

- Patented nVent CADDY Rod Lock “push-to-install” technology makes the installation of prefabricated light-duty trapezes or even single-rod application even faster

- Fine-tuning of the installation height can be done by spinning the threaded rod.

Safety Features

- Spring steel material for higher strength and durability

- Safety factor of 3:1 on static load

- Compliant with UL 2239 – Hardware for the support of conduit, tubing and cable

- nVent CADDY Armour Coating carries a 10-year warranty against corrosion

- The nVent standard for nVent CADDY Armour includes at least 1,000 hours resistance against red rust when tested per the ASTM B117, DIN 50021 or ISO/R1456 salt spray tests

- nVent CADDY Armour finish is RoHS & REACH Compliant.

www.transnet.co.nz

For further information please contact your local Powerbase Branch.