When it comes to keeping total cost of ownership down and boosting profitability, continuous operation and energy efficiency are essential. This is what ABB’s broad portfolio of motor starting and protection solutions delivers.

Thanks to their best-in-class and innovative technology, their solutions prevent downtime and can stand up to any conditions, as well as reduce CO2 emissions.

Reducing the total cost of ownership is key, however the purchasing price makes up only a fraction of the total cost of ownership.

The most overlooked costs are often the ones incurred by interrupting the process, in other words the ‘cost of not running’: equipment damage, lost revenue, late fees and lost opportunities, all impact the bottom line.

ABB’s advanced solutions help drive the costs down in this area via smart integrated data and predictive applications to keep your plant running.

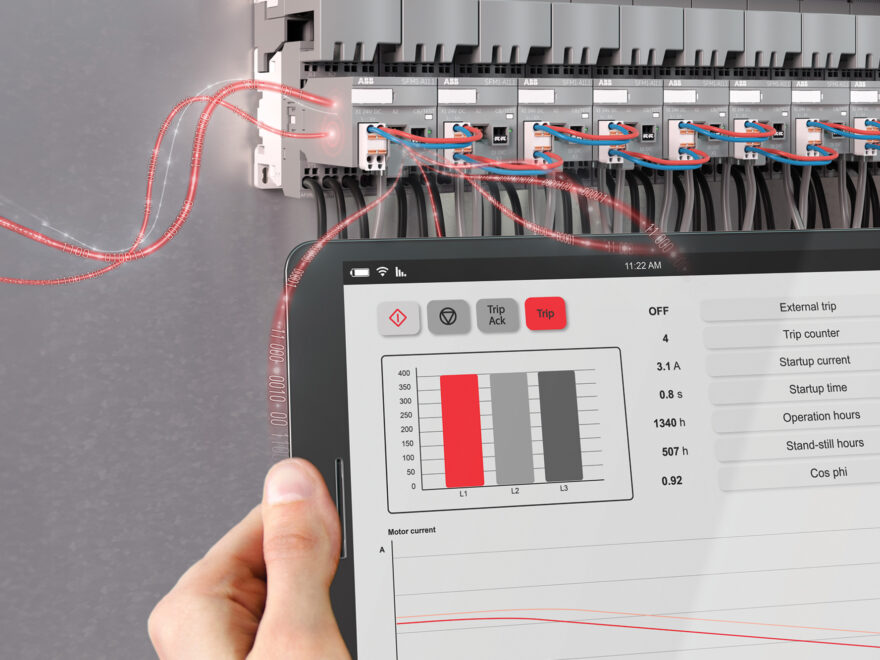

For example, with the SACE Tmax XT breaker range, trip unit settings performed via front display and Bluetooth and Ekip Mobile connectivity can save you up to 40% time overall, while up to 30% more data is available on the cloud, making diagnosis and maintenance much easier.

Alternatively, you can protect your motors at all times with their Universal Motor Controller UMC100.3, even if your control or communication system (Ethernet or Fieldbus) breaks down.

On the other hand, energy costs are a significant ‘cost of running’ and contribute decisively to the total costs of a motor system. For example, up to 80% reduced coil energy consumption with the AF contactor range which also means less heat is dissipated so that the installation density in the panel can be increased.

ABB’s low voltage motor starting, and protection solutions are IE3/IE4 compatible, offering users of high-efficiency motors solutions with small carbon footprints and low operation energy consumption.

ABB has been offering premium efficiency IE3 motors for years, leading the way towards even higher energy savings, effectively reducing the cost of running an electric motor-driven system.

And with their Selected Optimised Coordination (SOC) tool, choosing the right solution for your needs couldn’t be easier.

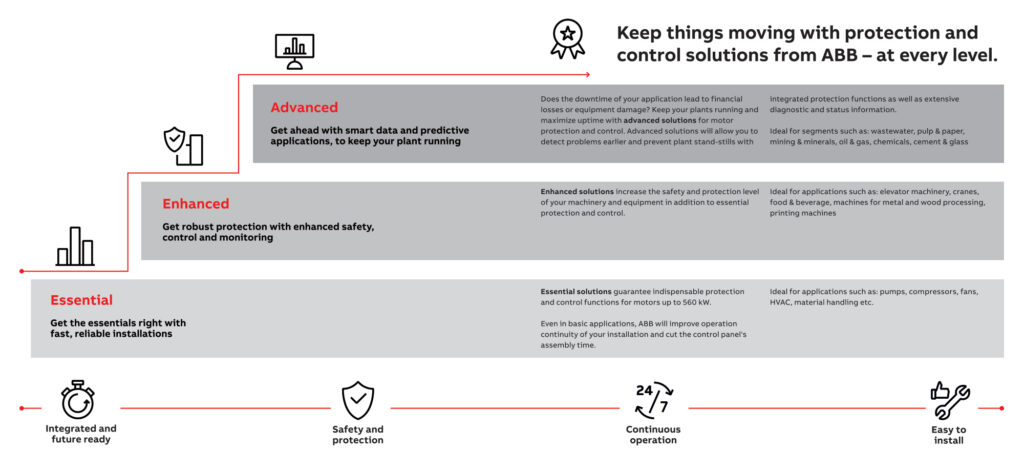

ABB provides coordination tables for the selection of low voltage equipment, specifically tested for starting and protecting IE3/IE4 motors in the SOC tool. Essential, enhanced and advanced solutions can be selected there.

Product selection for different types of starting methods are available as well, including direct-on-line, star-delta and softstarters. Usage of coordination tables helps reduce the time for selection and design of solutions as well as the risk of unwanted downtime, e.g. caused by nuisance tripping. This provides protection and safety, further driving down the total cost of ownership.

So don’t compromise. Keep things moving with protection and control – at every level. And whilst reducing your total cost of ownership concurrently lower your CO2 footprint with ABB’s solutions.

![]()