How to ensure a secure, long-lasting power connection for your electrical installation – the EverLink solution.

In the last issue we examined various common connection options and their limitations, here we conclude the article with a solution.

Overview

EverLink is a technology that offers customers reliable, tightened cables over a long-term duration to ensure a secure and reliable power connection. The EverLink solution is achieved by the user tightening the lug around the cable and loading a spring which compensates the loss of space due to the effect of creeping, as we have seen previously. Introduced in 2007 for the Schneider Electric TeSys range, this patented technology is available in two formats:

- A spring blade is added to the lug (TeSys for instance, applied for two cable lugs, allowing a longer stroke for the spring effect).

- The lug itself incorporates a special feature for the spring effect – this creates compactness for shorter lugs.

This spring effect replicates the behavior of screwless connections, which are creep compensated, while providing a high level of pressure between cable and product connection, and thus, a lower contact resistance.

Physical principles

EverLink – with TeSys

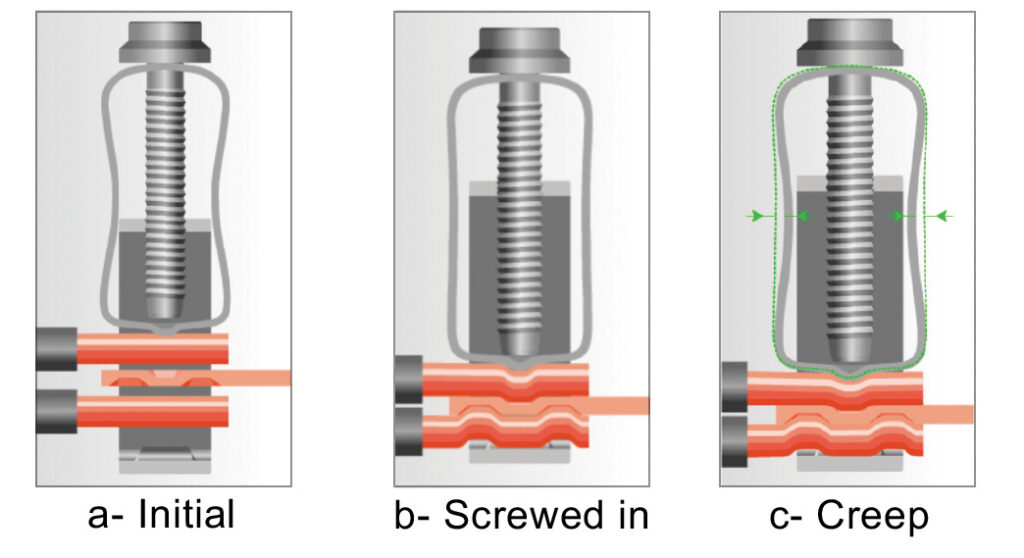

With this technology, the spring effect is stored in an elastic element that surrounds the screw, which deforms during tightening, transforming from an incurved shape (Figure 1-a) to a straight one (Figure 1-b). When the cable starts to creep, the elastic part tends to revert to its initial shape and provides sufficient pressure to avoid thermal runaway or other hazardous installation effects. Creep compensation is achieved as a result of the specific spring effect design.

Figure. 1.

Working Principle of EverLink TeSys

EverLink – with Compact NSXm and PowerPact B

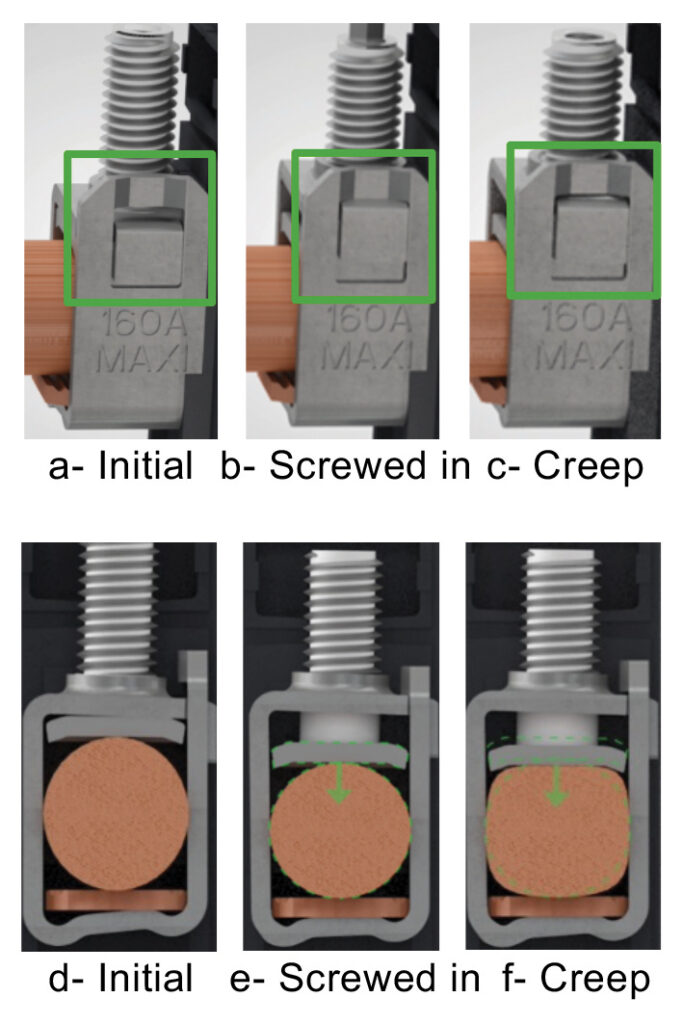

With this technology, the lug behaves slightly differently. Its shape is neither square nor rectangular but rather trapezoidal. Furthermore, the lug has an area of relative motion which allows elastic deformation before reaching the stop. From this position, the stiffness of the lug is similar to that of a regular lug.

Initially, the lug is in the bottom position (Figure 2-a&d). After screwing, it reaches the upper position (Figure 2-b&e) while the lug is being loaded, (shape changes from trapezoid to square). Once the cable begins to creep, the lug should revert to its initial position, whilst maintaining pressure on the cable (Figure 2-c&f).

Figure. 2.

Circuit breaker connection test

In November 2017, Schneider Electric’s test laboratories carried out comprehensive tests in which it compared three similar (160A) molded case circuit breakers to measure the effects of connection unscrewing. The circuit breakers tested were Schneider Electric’s Compact NSXm, as well as circuit breakers from two leading competitors. The objective of the tests was to measure the level of heat generated on the terminal of each circuit breaker as a result of unscrewing the connection of each, (thus emulating the cable creep and unscrewing effect caused by vibrations), at intervals of quarter turns up to a maximum of 1.25 turns. Each of the three circuit breakers was subjected to the same test in identical conditions.

The results of the testing concluded that Schneider Electric’s Compact NSXm molded case circuit breaker outperformed the competition. That’s to say, during testing, the Compact NSXm breaker generated the least heat of the three circuit breakers, by some margin, and as a result was the only one that did not trip after one complete screw turn. The competitors’ products no longer maintained sufficient pressure on the wire and therefore tripped when unscrewed by over a half turn. A study was done in parallel with TeSys GV4 motor circuit breaker and two leading competitors showing similar findings. These studies thus showed the resounding strength of the EverLink power connection technology across both the Compact NSXm and TeSys range.

Benefits of EverLink

Safety

EverLink ensures a more reliable connection by providing a spring pressure reserve on cables in the event of thermal dilatations, creeping, or loosening as a result of external vibrations. This pressure reserve maintains the connection in a wide range of operational environments by ensuring lower contact resistance, and thus, a lower temperature rise. Not only does this reduce the risk of thermal runaway, which can potentially lead to a fire, it also diminishes the risk of the cables being pulled out of their power connections during a short circuit.

Maintenance

As EverLink’s spring effect ensures a tight connection over time, a retightening campaigns is no longer required each year. This frees up time for maintenance technicians who traditionally have had to invest more time in this type of preventive maintenance. Furthermore, where thermal imaging is used according to local regulations, the facility managers can have peace of mind knowing that the EverLink connections have creep compensating technology.

Continuity of service

When there is a creep effect present, in certain cases, the excessive heat generated at the connector can be detected by the thermal overload protection (bimetallic strip) causing the circuit breaker to trip. This unwanted trip could potentially halt a continuous process leading to raw material scrap or loss of productivity. As seen in the circuit breaker connector test, the leading competitors without EverLink technology, inadvertently tripped due to the connectors overheating. It is time consuming for the maintenance technicians to manually reset the circuit breakers and this could be a repetitive problem.

How to ensure a perfect installation

Here are a few tips for ensuring that EverLink is installed correctly and to avoid poor connections during product life:

- Use a cable that is adapted to the connection (section, material, cable type..)

- Prepare the cable accordingly, (twisting of cables, clamps, for example) and insulate the cable to the required length.

- Unscrew the connection entirely if necessary.

- Insert cable and tighten using the recommended tools. Be aware that tightening an Everlink connection may provide a different feel due to spring effect of the lug.

- Do not overtighten, and do respect torque, as recommended by using a torque wrench and torque breakaway bits.

- Ensure cables are securely tightened in connection by gently pulling on them.

- Check the installation on an annual basis, using thermal screening. In the event that thermal screening is not available, carry out an additional re-tightening.

Conclusion

Safety and reliability are the two principal considerations for electrical installation power connections. If these factors are not given sufficient attention, installations may be at risk of electrical fires and other electrical-related damage. Schneider Electric EverLink technology is designed to offer customers peace of mind in terms of reliability, maintenance and continuity of service. Because EverLink requires no regular re-tightening of its power connections, maintenance is thus optimized.

Furthermore, in the past, customers have sometimes suffered from installations in which overheating of connectors has caused inadvertent circuit breaker tripping. Likewise, customers have for a long time faced the risk of overheating – which can lead to serious damage to circuit breakers and/or associated wires.

Thanks to its patented spring effect technology, EverLink mitigates the effect of

creeping, ensuring that power connection cables are kept tight, to ensure customers have a reliable, long-lasting connection within their electrical installations.