In Industrial Precision Cooling Applications

5 WAYS TO ACHIEVE ENERGY EFFICIENCY in Industrial Precision Cooling Applications

The demand for increased energy efficiency is unrelenting, whether it’s government regulations or simply demands from the corporate boardroom. And it’s hard to argue, given improving energy efficiency means saving money as well as the planet. What’s not to like?

Industrial environments often require precise levels of cooling, which can be expensive indeed. Pharmaceutical, electronic and chemical companies are just some of the industries that require tight control of temperature and humidity to prevent bacteria growth, chemical reactions or adverse effects on materials. In many cases, that means cooling units are running virtually all the time, chewing up electricity – and dollars.

But there are ways that industrial companies can reduce the energy their cooling units consume without sacrificing the precise control that their applications demand. Here are five attributes to look for in cooling systems that will save energy and money.

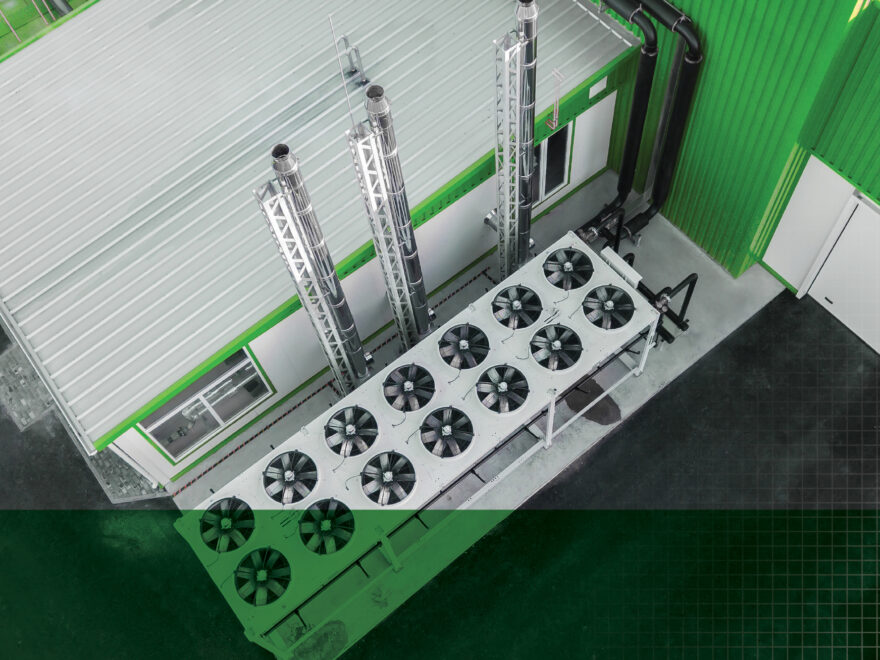

Integrated, “free” cooling

Some cooling systems can take advantage of cold outside air to maintain precise temperatures indoors. Also called economizer mode, these systems eliminate compressor operation during times when the outdoor temperature is cool enough to deliver whatever temperature is required inside.

The technology has been used to cool data centres for years, and in geographies where you may not think it’d be viable, including desert climates like Las Vegas. Savings of 50% or more are well within reach.

Variable speed drive compressors

Once upon a time an air conditioner was either on or off, meaning the compressor and drive fans were running, or they weren’t. Today’s units bring more finesse to the job, with electronically controlled drive fans that can run just fast or slow enough to match the required cooling load. That ability to run at something less than 100% power can dramatically reduce energy consumption.

Tandem compressor technology

Another way to increase efficiency is by having two compressors share a single refrigerant circuit. When you don’t need the cooling capacity of both compressors, one turns off and the other takes over the entire refrigerant circuit. This allows the unit to work more efficiently at partial load and increase the Coefficient of Performance (COP) when full compressor capacity is not required.

High-efficiency refrigerants

Refrigerant technology is also advancing in both efficiency and environmental safety. A new breed of refrigerants (named R410a and R134a, if you want to get technical) can absorb more heat than their predecessors, making them more efficient. What’s more, they have zero effect on the ozone, making them more environmentally friendly.

Oil-free compressors

The latest in compressor technology uses magnetic bearing technology instead of oil-lubricated bearings. In addition to reducing friction and maintenance, these compressors draw significantly less power; newer chiller plants using this technology draw half the current of older models. It also reduces noise and vibration while improving reliability.

Schneider Electric has been a leader in cooling technology for decades. Our systems can be found in data centres around the globe, and in some of the most demanding of environments. We’re now bringing our cooling experience to bear on a wider range of applications, including precision cooling for industrial environments.